Description

HUFFORD SHEET STRETCH FORMER

Model 46, Serial Number 10

SPECIFICATIONS

CAPABILITIES: Sheet Stretcher Leveling, Stretch Wrap Forming.

DIE BED IN VERTICAL PLANE

SHEET CAPACITY Width x Length 66" X 144"

(1,676.4mm x 3,6576mm)

10-JAWS:

Jaws Rotate. Swing Left or Right. Articulate.

Adjust from Flat to Concave. Oscillation

Number of Segment 10

Length of Jaws 76" (1,930.4mm)

10 Jaws that create a Curved and 1-Centroid Jaw located in center.

Jaw Oscillation cylinder 10" stroke, Oscillates Jaw Assembly 10 degrees

each side of Centerline in Planes of Sheet.

Jaw Assembly Rotates from Vertical.

Capacity of each Carriage Jaw 150 Ton

DIE HEIGHT Maximum 72" (1,828.8mm)

DIE DEPTH Maximum 42" (1,066.8mm)

DIE LENGTH for 180 degree bend at full length 190" (4,26mm)

Minimum 40" (1,016mm)

DIE TABLE:

5-DIE BLOCKS POSITIONS 12" (304.8mm) on centers

Working Area Width x Height 24" x 72" (685.8mm x 1,828.8mm)

OPERATOR CONTROL STATION:

Pump Start / Stop Buttons.

Left Hand & Right-hand Jaw Gripper Cylinders.

Left Hand & Right-Hand Tension Cylinders.

Left hand & Right-Hand Jaw Cylinders.

Left Hand & Right-Hand Jaw Rotation and Oscillation Cylinders.

Straightening Cylinder. Jaw Curing Cylinders.

Pressure Gauges.

MOTOR DRIVES: wired 440 volts

HYDAULIC SYSTEMS (Separate Systems) 5

2- Arm Actuating Cylinders Circuits each with separate power

plants and piping, but identical.

1- Tension Cylinder Circuit, operating both pairs of cylinders,

but with separate controls for each pair of cylinders.

1- Jaw Operating Circuit with separate controls for each jaw and

an Oscillation, Rotation and Swing Circuit with individual

controls for each.

1- Die positioning Cylinder Circuit is on the same circuit as

the Left-Hand Arm actuating Cylinder

POWER UNITS:

Tension, Rotation, Oscillation & Jaw Cylinder Hydraulic Pumps each 60 HP 220/440v

Arm Actuating Cylinder Pumps each is driven by 15 HP 220/440v

Gripper Jaws Cylinder Pump 3 HP 220/440v

EQUIPPED WITH:

Operator Control Station.

COMPLETE FACTORY SAFETY GUARDS

![10027-1,hufford sheet stretch former,mdl 46,150-T,76 in W jaws-articulate & sw L-R & oscillate,die L for 180 deg 190 in,die ht 72 in,depth 42 in,Serial 10 150 tons, Hufford A-46 Sheet Stretch Forming Press Machine, Sheet length 66 inch x 144", Depth 42", with 76" Jaws Articulating & Swinging left and right & Oscillate, Die length 190", Serial Number10 [S8120-10027]](https://centurymachinery.com/wp-content/uploads/2021/04/10027-1hufford-sheet-stretch-formermdl-46150-T76-in-W-jaws-articulate-sw-L-R-oscillatedie-L-for-180-deg-190-indie-ht-72-indepth-42-inSerial-10.jpg)

![10027-1,hufford sheet stretch former,mdl 46,150-T,76 in W jaws-articulate & sw L-R & oscillate,die L for 180 deg 190 in,die ht 72 in,depth 42 in,Serial 10 150 tons, Hufford A-46 Sheet Stretch Forming Press Machine, Sheet length 66 inch x 144", Depth 42", with 76" Jaws Articulating & Swinging left and right & Oscillate, Die length 190", Serial Number10 [S8120-10027]](https://centurymachinery.com/wp-content/uploads/2021/04/10027-1hufford-sheet-stretch-formermdl-46150-T76-in-W-jaws-articulate-sw-L-R-oscillatedie-L-for-180-deg-190-indie-ht-72-indepth-42-inSerial-10-1.jpg)

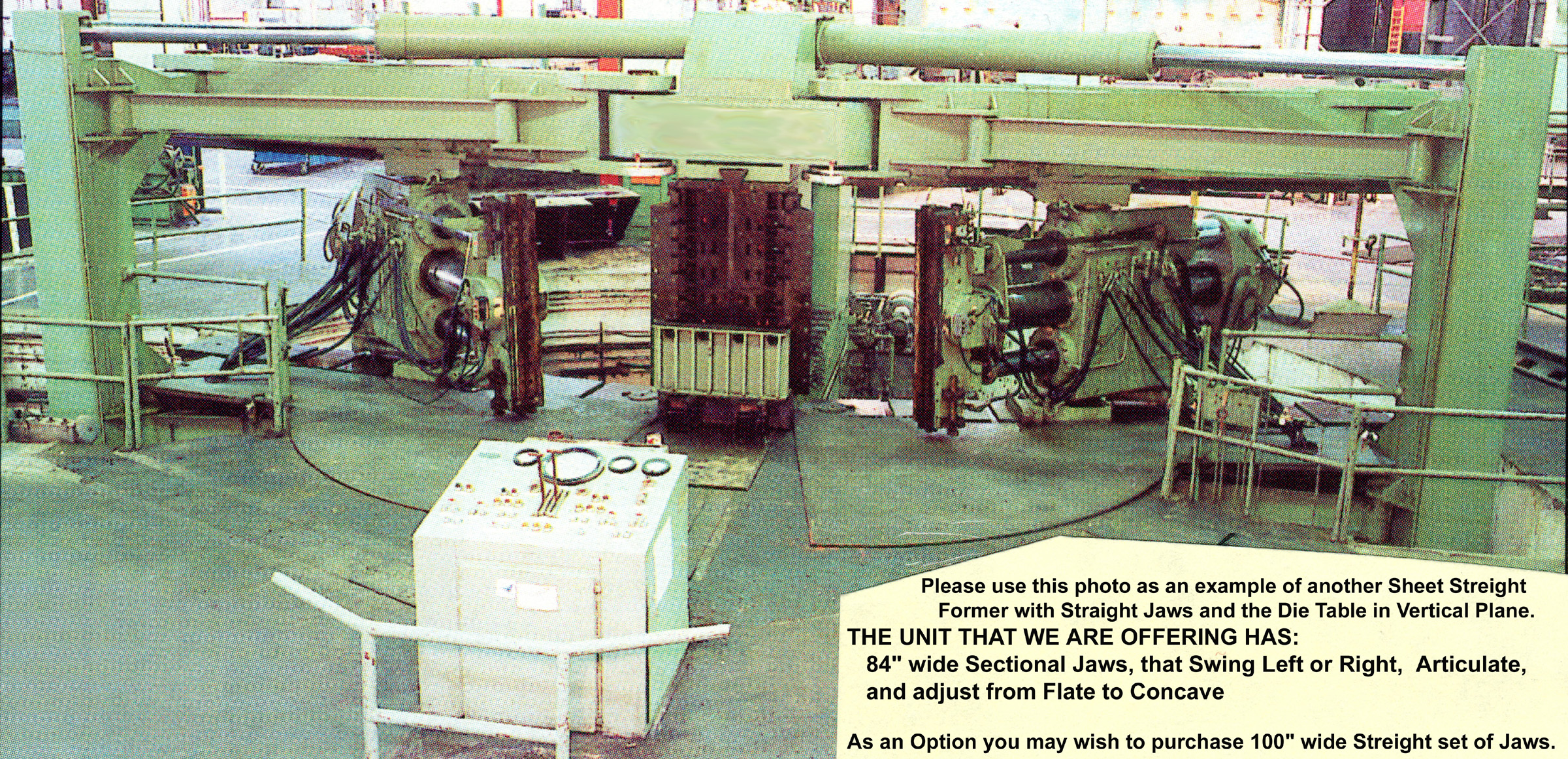

![600 tons, Sheridan Gray Sheet Extrusion Stretch Wrap Former, Model E-600-24, Articulate 84" Jaws, Swing left & right & oscillate, Stroke Length 288", Die Length 192" [S8120-10029] - Century Machinery 600 tons, Sheridan Gray Sheet Extrusion Stretch Wrap Former, Model E-600-24, Articulate 84" Jaws, swing left & right & oscillate, Stroke Length 288", Die Length 192" [S8120-10029]](https://centurymachinery.com/wp-content/uploads/2021/04/10029-1A-sheridan-gray-sheet-extrusion-stretch-wrap-former_E-600-24_600-T_84-in-jaws_articulate_sw-L-R-oscillate_str-288-in_die-length-192-in_Example-Photo-300x300.jpg)

![20 Tons, Cyril Bath CNC Dual Parts Extrusion Stretch Wrap Forming Press Machine, Model V-20, Distance between primary jaws 168", Distance between second jaws 92.5", Carriage travel 39", Serial M10307 [S8120-9476-1] - Century Machinery 20 Tons, Cyril Bath CNC Dual Parts Extrusion Stretch Wrap Forming Press Machine, model V-20, Distance between primary jaws 168", Distance between second jaws 92.5", Carriage travel 39", Serial M10307 [S8120-9476-1]](https://centurymachinery.com/wp-content/uploads/2021/04/9476-1_cyril-bath-cnc-dual-jaws_single-plain-stretch-wrap-forming-press_V-20_mfg-03_F-1-300x300.jpg)

![30 tons, Cyril Bath-Alstom V-30-300 CNC Extrusion and Sheet Stretch Wrap Forming Press Machine, Distance between 6" Jaws 300", Tension Cylinder Stroke 30", Independent Arms Movement, Serial Number M-7416, [S8120-10287] - Century Machinery 30 tons, Cyril Bath-Alstom V-30-300 CNC Extrusion and Sheet Stretch Wrap Forming Press Machine, Distance between 6" Jaws 300", Tension Cylinder Stroke 30", Independent Arms Movement, Serial Number M-7416, [S8120-10287]](https://centurymachinery.com/wp-content/uploads/2021/04/10287-1-cyril-bath-alstom-CNC-stretch-wrap-former-V30-300-30-T4x5-in-jawsBJ-300-in-Str-30-inindepend-arms-Mfg-98-Serial-M-7416-L-F-300x300.jpg)

![10 tons, Cyril bath V10 CNC Extrusion Stretch Wrap Forming Press Machine, Distance between jaws 113", Jaws Rotate, Swing Right - Left and Tilt up-down, rise and fall each, Independent Arm Movement, Serial Number 101103, [S8120-10232] - Century Machinery 10 tons, Cyril bath V10 CNC Extrusion Stretch Wrap Forming Press Machine, Distance between jaws 113", Jaws Rotate, Swing Right - Left and Tilt up-down, rise and fall each, Independent Arm Movement, Serial Number 101103, [S8120-10232]](https://centurymachinery.com/wp-content/uploads/2021/04/10232-1-Cyril-Bath-V10-CNC-Stretch-Former-Quad-Axis-Serial-101103-Front-Right-Side-Quad-Axis-Jaw-Carriage-Assembly-_-Die-Clamps-300x300.jpg)

![11 tons NAS Plant Division Extrusion Stretch Wrap Forming Press Distance between 3" Gripper Jaws 136" Tension Cylinder stroke 13" Simultaneous Arms Movement, Serial number NAS3-19805, Inventory referenceS8120-10423 - Century Machinery 11 tons, NAS Plant Division Extrusion Stretch Wrap Forming Press, Distance between 3" Gripper Jaws 136", Tension Cylinder Stroke 13", Simultaneous Arms Movement, Serial Number NAS3-19805 [S8120-10423]](https://centurymachinery.com/wp-content/uploads/2021/04/10423-1-NAS-plant-division-stretch-wrap-forming-press-11-tons-3-inch-jawsbetween-jaws-136-inch-tension-str-10-inch-NAS-3-19805Rside-F-300x300.jpg)