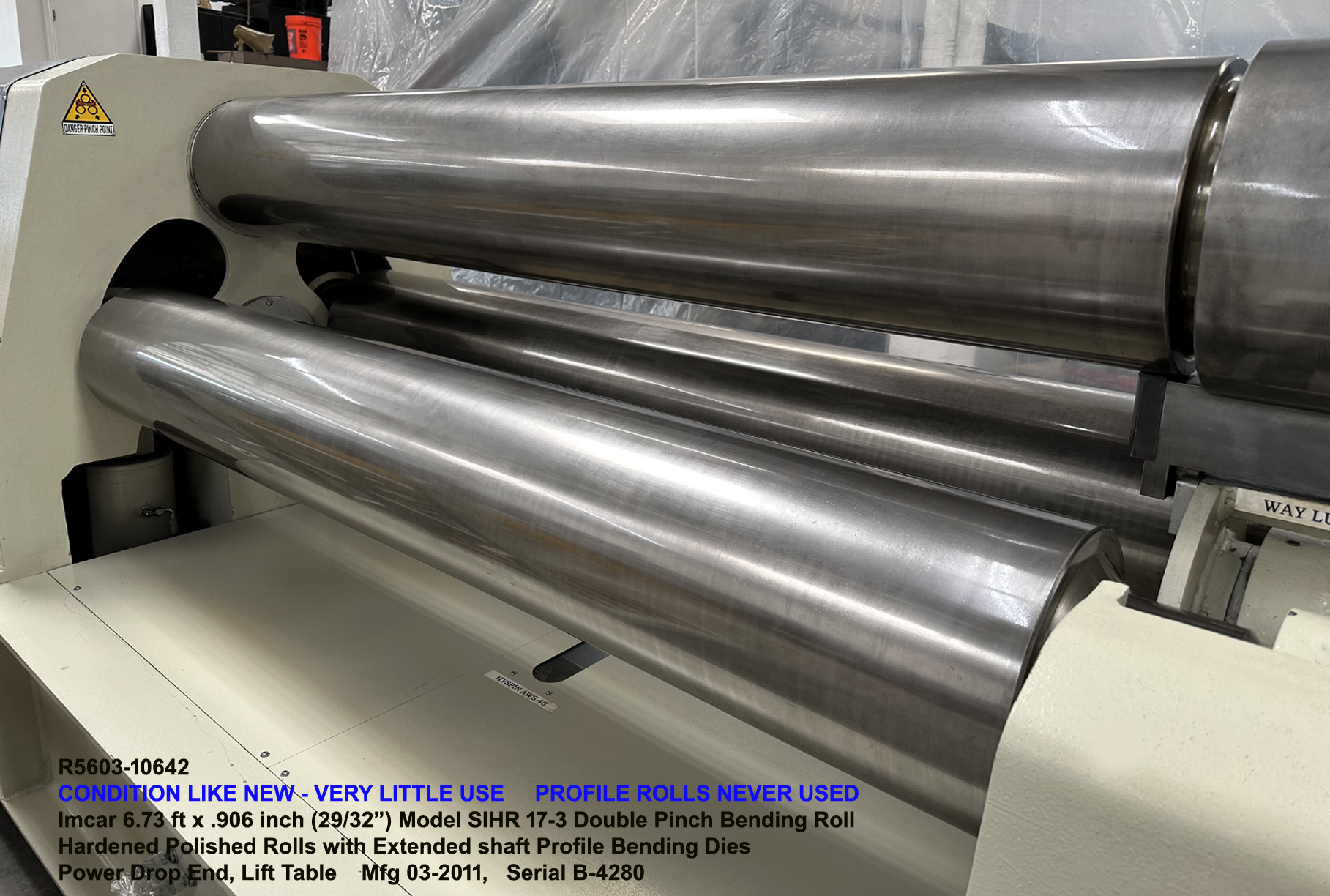

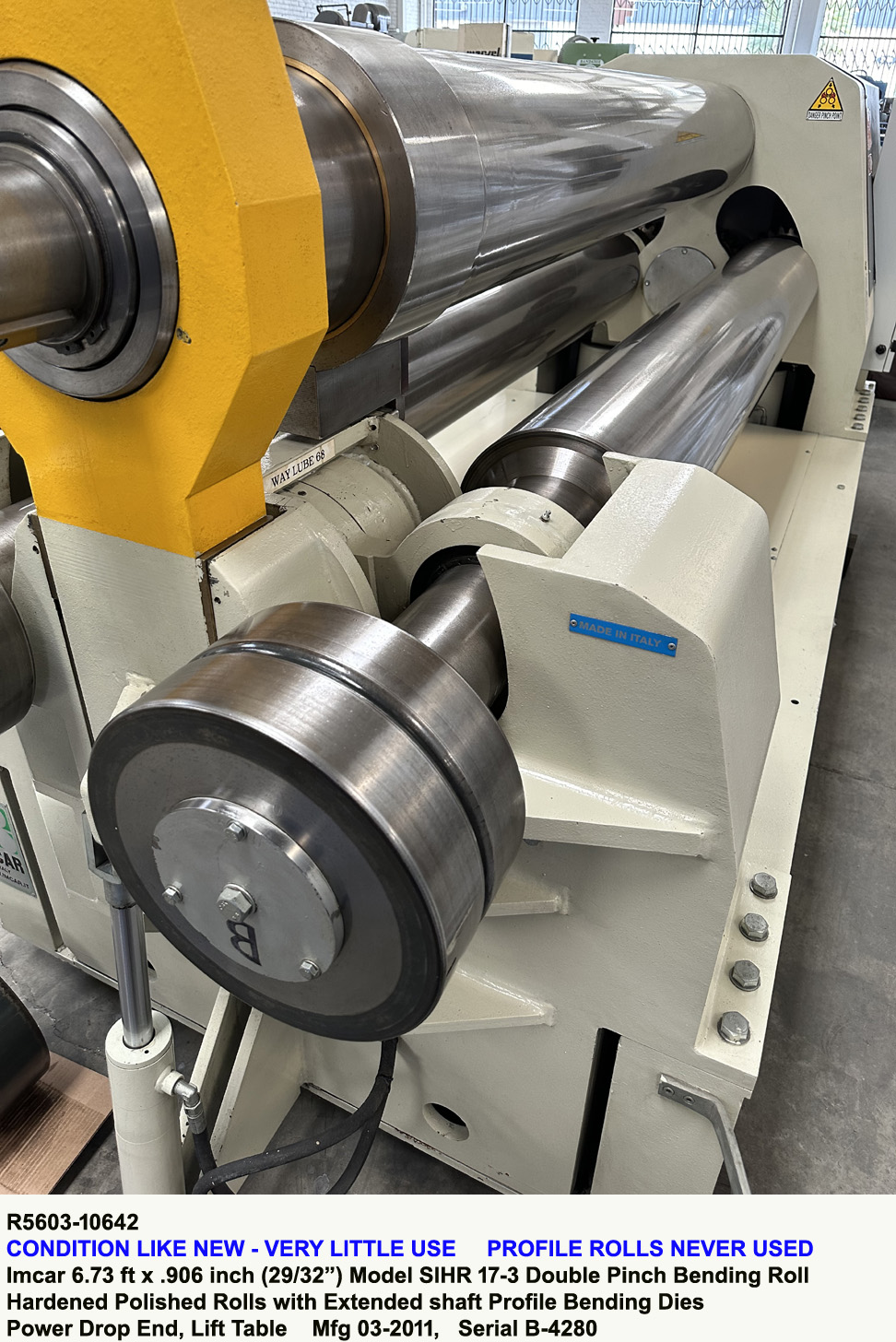

Description

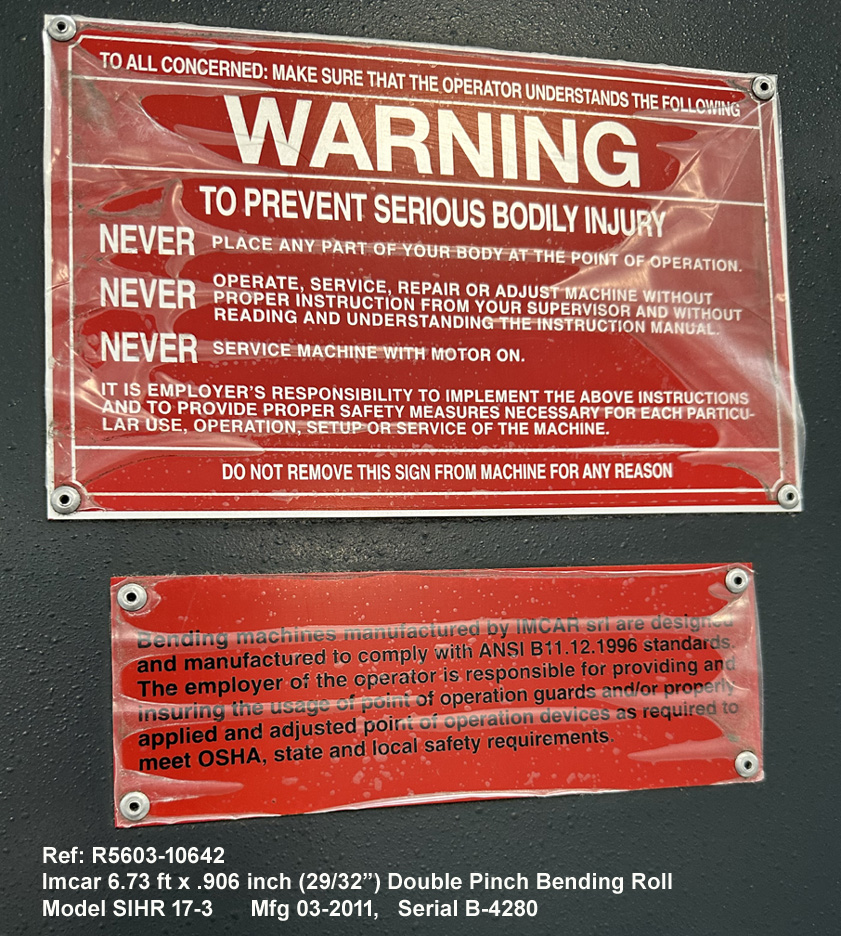

IMCAR HYDRAULIC 3 ROLL DOUBLE PINCH PLATE BENDING ROLL

Model SIHR 17/3, Serial Number B-4280, Date Mfg’d 03-2011

Ship Date 06/2011Model 300-10, Flush Floor Mount, Serial Number 2309

Condition: Excellent LIKE NEW Very Little Use

SPECIFICATIONS

WORKING LENGTH OF ROLLS: 80.7″ (6′-725″) (2050mm).

CAPACITY: 1.3 Ø Roll C thickness 0.669″ (11/16″) (17mm).

3 x Ø Roll C thickness 0.905″ (29/32″) (23mm).

ROLLS: HARDENED, Induction Hardened 54-56HRC

and POLISHED

Top Roll (C) Diameter.12.99″ (330mm).

Bottom Lateral Rolls (A / B) Dimeter each 12.21″ (310mm)

Double hydraulic motors coupled to planetary gears for Rotation of the 3-rolls.

Automatic compensation of the peripherical speed of Top Roll.

Bottom Rolls A & B, each with Power Elevation.

Planetary movement of bending rolls with short inter-axis to reduce the flat

part (PRE-BENDING.

Extended Shaft on all rolls for use of Section Bending Dies.

Cone Equipment. Incline Control.

Hydraulic inclination of lateral Rolls for conical bending from control desk. Hydraulic parallelism of the rolls.

EQUIPPED WITH:

Induction Hardened Rolls 54-56HRC Polished Roll Surface.

1- set Profile Bending Rolls (Section Die).

Cone Bending Device. Instruction Manual.

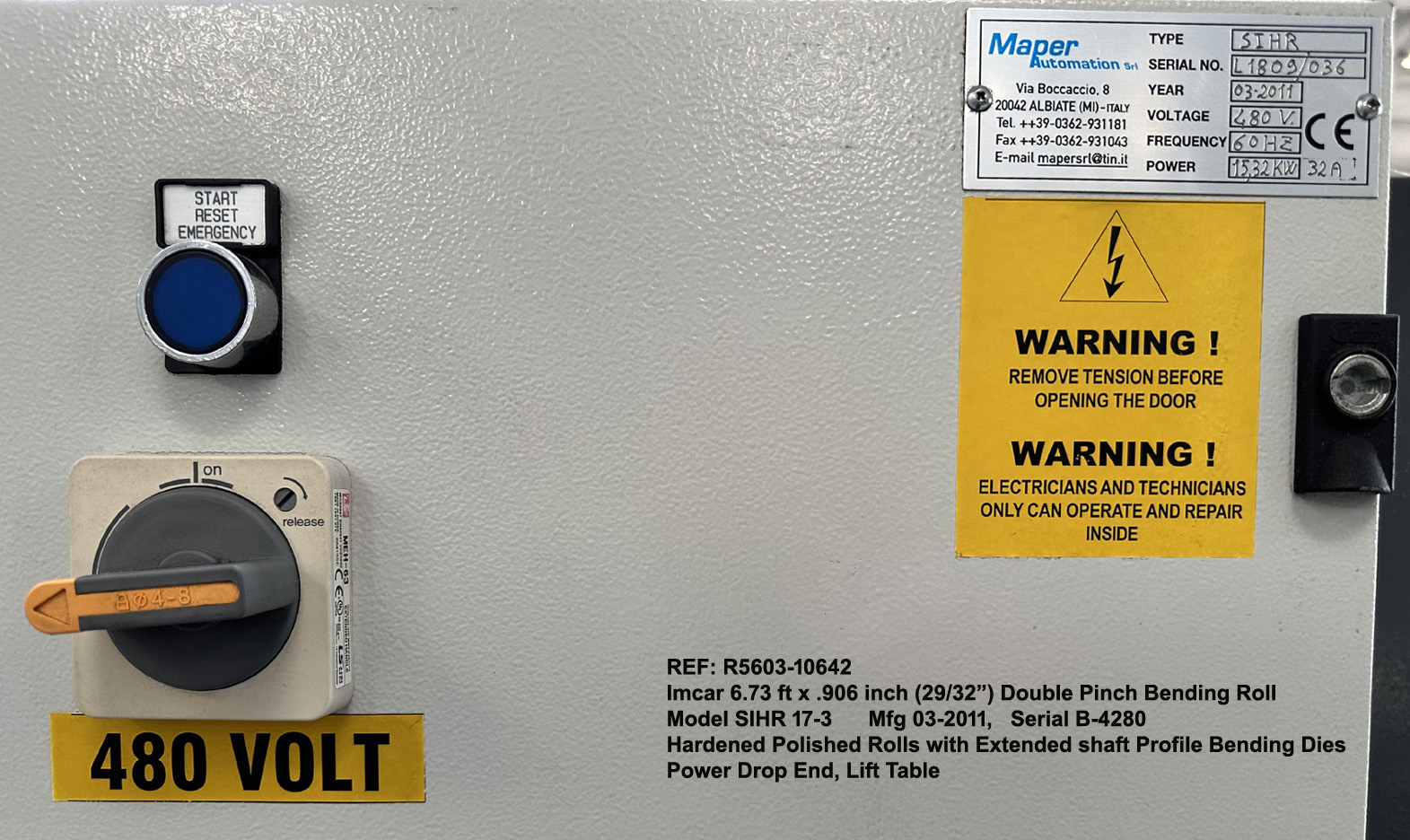

MOTOR PUMP DRIVE wired 480 volts, 3 phase

Rolls driven by Double hydraulic motors 20.40 hp (15kw). 220/440 volt.

OPERATOR CONTROL DESK on wheels:

Main switch Keyed On/ Off. Power On Light.Emergency Stop Button.

General Pilot Light Power On.

Hydraulic Motor Start Button & 2-Positions Switch.

LED READ-OUT Display: A/B LATERAL ROLLS Lifting & Lowering

(4 total, 2 for each).

Lateral Rolls A/B control Rotation of Sheet and Lowering / Lifting in

Parallel. Rolls Forward/Reverse Buttons.

Drop End Open / Close Switch.

Lift Table Raise/ Lower Switch.Roll Direction forward / Back Buttons.

The push-button controls allow the lateral roll to be moved and rotated, while

the roll parallelism is controlled hydraulically.

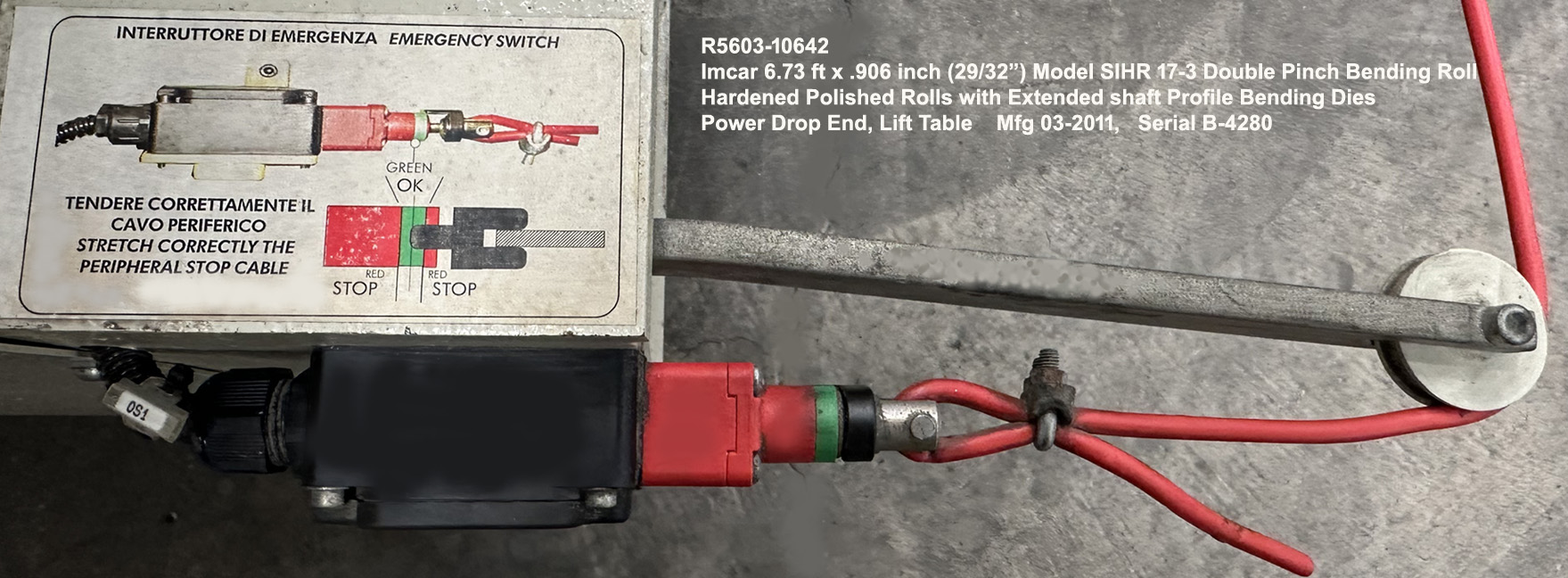

EMERGENCY STOP Trip Wire (Electrical Current Shut Off.

COMPLETE FACTORY SAFETY GUARDS

Dimensions: ROLL 75″ FB x 168″ LR x 70″ Height

(1905mm FB x 4,267.2mm LR x 1,800mm Ht.)

LIFT ARM 53″ FB x 66″ LR x 46″ Ht

(1.346.2 FB x 1,676.4 LR x 1,168.4mm)

OPERATOR DESK 24″ FB x 28″ LR x 46.5″ Ht

(609.6mm FB x 711.2mm LR x 1,181.1mm Ht.

Approximate weight 19,700 lbs.

Replacement $245,000.00 usd

Our price on request at our Los Angeles, CA. showroom

Respectfully submitted

CENTURY MACHINERY CO., INC.

Please feel free to contact us for more info.

![62" x 0.125" Hendley Whittemore Initial Pinch Bending Roll, Model 3-D-5, 10 Gauge, Roll diameter 5.2", Power Elevation on Rolls, Serial Number 16240 [R5603-9572] - Century Machinery 62" x 0.125" Hendley Whittemore Initial Pinch Bending Roll, Model 3-D-5, 10 Gauge, Power Elevation on Rolls, Serial Number 16240 [R5603-9572]](https://centurymachinery.com/wp-content/uploads/2021/04/9572-1_hendley-whittemore-initial-pinch-bending-roll_62-in-x-0.125-in_mdl-3-D-5_10-ga_pwr-elev_Serial-16240-300x300.jpg)

![24" x 20 gauge Roper Whitney Pexto Initial Pinch Slip Bending Roll, Model 383, Roll Diameter 2", with 3-wire Grooves, Serial Number 1780-6-00 [R5603-10347] - Century Machinery 24" x 20 gauge Roper Whitney Pexto Initial Pinch Slip Bending Roll, Model 383, Roll Diameter 2", with 3-wire Grooves, Serial Number 1780-6-00 [R5603-10347]](https://centurymachinery.com/wp-content/uploads/2021/04/10347-1-roper-whitney-pexto-initial-pinch-slip-bending-roll-24-in-x-20-ga-mdl-383-roll-dia-2-in-3-wire-grooves-Serial-1780-6-00-F-300x300.jpg)

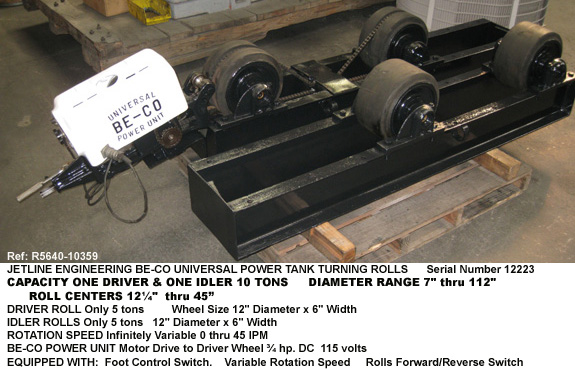

![10 Ton Jetline Universal Power Tank Turning Rolls, Diameter Range 7" thru 112", Wheel 12" diameter x 6" width, Power unit Varible Speed Drive Motor 115 volts, Serial Number 12223 [R5640-10359] - Century Machinery 10 Ton Jetline Universal Power Tank Turning Rolls, Diameter Range 7" thru 112", Wheel 12" diameter x 6" width, Power unit Varible Speed Drive Motor 115 volts, Serial Number 12223 [R5640-10359]](https://centurymachinery.com/wp-content/uploads/2021/04/10359-1-10-ton-jetline-universal-power-tank-turning-rolls-dia-range-7-in-112-in-wheel-12-in-dia-x-6-in-width-power-unit-vari-drive-115v-Driver-_-Idler-300x300.jpg)