75 tons CYRIL BATH STRETCH-WRAP FORMING PRESS MACHINE

Model V-75, Serial Number 80204

SPECIFICATIONS

TENSION CYLINDER PULL:

Stroke 30" (762mm)

Bore 10" (254mm)

Net Area, 58.9 inches 2 (1,496.06mm)

Maximum Pull @ 2600 PSI 75 Tons

Minimum 5 Tons

TENSION CYLINDER SWING +/- 30 Degrees

TENSION CYLINDER BRACKET POSITIONING

Infinite between Limits

ARM CYLINDER:

Bore 7" (177.8mm)

Rod 3.5" (8.9mm)

Stroke 50" (1,270mm),

Net Area (Wrapping 19.25" (488.95mm) Squared

Maximum Thrust (Wrapping Force) @ 2500psi = 36Tons

ARM WRAP Controlled independently through 100 percent

JAW AXIAL ROTATION each Jaw +/- 90 Degrees

Total +/- 180 Degrees

DISTANCE BETWEEN JAWS:

Minimum 24" (609.6mm)

Maximum 350" (8,890mm)

DIE LENGTH:

180 Degree Bend @ Full Tonnage, Maximum 78" (1,905mm)

180 Degree Bend @ any Tonnage, Minimum 20" (508mm)

OPERATING (PSI) 2,500

DIE TABLE: (2) T-Slots

Working Surface, 72" W x 50" D x 36" Height

(1,28.8mm x 1,270mm x 914.4mm)

MOTOR DRIVE: Wired 440 volts, 3-phase

Hydraulic Pump 50 H.P. 220/440 volts, 3 Phase

Right and Left Carriage (Two) 2 H.P. 220.440 volts

CENTER CONTROL STATION:

Updated 1/22/98 with GEC. Alsthom Multi-Tasking Operating System.

With QNIX Operating System. Power Supply. Hard Drive.Floppy Disk.

101 Keyboard. Color CRT. IDE Removal Drive.

High Speed Communication Card. Modem Card.

Main Console Switch Layout: Power Key Lockout.

Power On/Off Switch. Hydraulic On/Off Switch.

T/C Pressure Control Potentiometer. OK to Start Hyd. Indicator.

Arm Forward/Back Switches. Tension Cylinder In/Out Switches.

Right & Left Jaw Operation Buttons. Low Oil Shutoff.

High Temp. Shutoff. Carriage Switches.

Tension Cylinder Pressure Control. Hydraulics Running.

Right & Left Jaw Operator Stations both with: Emergency Stop Button.

Jaw Open/Close Buttons. Jog In/Out Buttons.

Left Operators Station Located front of Table: Emergency Stop Button.

Snug Button. Unload Button. Pre Button. Wrap Button.

Arm T/C Stop. Post. Relax Button. Load Button. LTC In/Out

Button. LTC Stop. Left Arm Back/FWD., Left Arm Stop.

Left Carriage In/Out. Left Jaw Open/Close.

Open Both Jaws. D.C. Common.

Program Switches: These switches duplicate the functions on

the Console Programmable Switches.

Right Operator Station Locate front of table: Emergency Stop Button.

RTC In/Out Buttons. Right Arm Back/FWD Buttons.

Right Arm Stop Button. Right Jaw Open/Close Buttons.

Right Carriage In/Out Buttons. D.C. Common.

EQUIPPED WITH:

3-Sets of Jaws.

2-Die Post 4" (101.6mm) diameter.

Manual for: Press Operations. Calibration.

Machine Maintenance & Electrical Control System.

Manufacturers schematic drawings for: Hydraulics,

Electrical, Operation and Diagram Software.

Control Specifications.

COMPLETE FACTORY SAFETY GUARDS

Approximate weight 40,000 lbs.

![17166-1_cyril bath cnc stretch wrap forming press_vera V75_75T_BJ 350 in_Serial 80204_Overall copy 75 tons, Cyril Bath Vera V75 CNC Stretch Wrap Forming Press, Distance Between 8 inch Jaws 350", Stroke 30", Die Length 78", Serial Number 80204, [S8120-17166]](https://centurymachinery.com/wp-content/uploads/2021/06/17166-1_cyril-bath-cnc-stretch-wrap-forming-press_vera-V75_75T_BJ-350-in_Serial-80204_Overall-copy.jpg)

![17166-2_cyril bath cnc stretch wrap forming press_vera V75_75T_BJ 350 in_Serial 80204_Ctrl-F 75 tons, Cyril Bath Vera V75 CNC Stretch Wrap Forming Press, Distance Between 8 inch Jaws 350", Stroke 30", Die Length 78", Serial Number 80204, [S8120-17166]](https://centurymachinery.com/wp-content/uploads/2021/06/17166-2_cyril-bath-cnc-stretch-wrap-forming-press_vera-V75_75T_BJ-350-in_Serial-80204_Ctrl-F.jpg)

![17166-3_cyril bath cnc stretch wrap forming press_vera V75_75T_BJ 350 in_Serial 80204_Rear 75 tons, Cyril Bath Vera V75 CNC Stretch Wrap Forming Press, Distance Between 8 inch Jaws 350", Stroke 30", Die Length 78", Serial Number 80204, [S8120-17166]](https://centurymachinery.com/wp-content/uploads/2021/06/17166-3_cyril-bath-cnc-stretch-wrap-forming-press_vera-V75_75T_BJ-350-in_Serial-80204_Rear.jpg)

![17166-4_cyril bath cnc stretch wrap forming press_vera V75_75T_BJ 350 in_Serial 80204_Ctrl Station 75 tons, Cyril Bath Vera V75 CNC Stretch Wrap Forming Press, Distance Between 8 inch Jaws 350", Stroke 30", Die Length 78", Serial Number 80204, [S8120-17166]](https://centurymachinery.com/wp-content/uploads/2021/06/17166-4_cyril-bath-cnc-stretch-wrap-forming-press_vera-V75_75T_BJ-350-in_Serial-80204_Ctrl-Station.jpg)

![20 tons Hufford L&F A-7 Extrusion Stretch Wrap Forming Press Machine Distance between 6" Gripper Jaws 202" with Bulldozer Die Clamp, Serial Number 80508, Inventory Reference S8120-10201-519 - Century Machinery 20 tons, Hufford L&F, A-7 Extrusion Stretch Wrap Forming Press Machine, Distance between 6 inch gripper jaws 202 inch, with Bulldozer die clamp, Serial Number 80508 [S8120-10201-519]](https://centurymachinery.com/wp-content/uploads/2021/04/10201-1-Hufford-A7-20-T-202-in-BJ-Front-Serial-Number-80508-1-300x300.jpg)

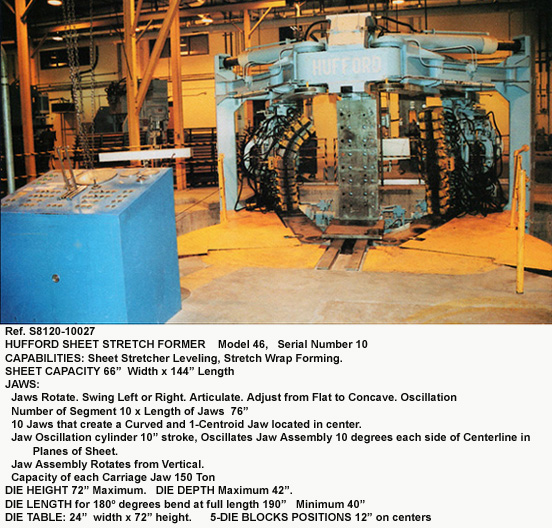

![150 tons, Hufford A-46 Sheet Stretch Forming Press Machine, Sheet length 66 inch x 144", Depth 42", with 76" Jaws Articulating & Swinging left and right & Oscillate, Die length 190", Serial Number 10 [S8120-10027] - Century Machinery 150 tons, Hufford A-46 Sheet Stretch Forming Press Machine, Sheet length 66 inch x 144", Depth 42", with 76" Jaws Articulating & Swinging left and right & Oscillate, Die length 190", Serial Number10 [S8120-10027]](https://centurymachinery.com/wp-content/uploads/2021/04/10027-1hufford-sheet-stretch-formermdl-46150-T76-in-W-jaws-articulate-sw-L-R-oscillatedie-L-for-180-deg-190-indie-ht-72-indepth-42-inSerial-10-300x300.jpg)

![Hufford A-12 Extrusion & Sheet Stretch Wrap Forming Press Machine - 60 tons - Distance between jaws Minimum 28" - Maximum 264" - Sheet Jaws 20" wide and Extrusion Gripper Jaws 6 inch - Tension Cylinder Stroke 30", Independent Arm Movement, Serial Number 40, Inventory Reference S8120-10342 - Century Machinery 60 tons, Hufford A-12 Extrusion & Sheet Stretch Wrap Forming Press Machine, Distance between jaws Minimum 28", Maximum 264", Sheet Jaws 20 inch wide, Extrusion Gripper Jaws 6 inch, Tension Cylinder Stroke 30", Independent Arm Movement, Serial Number 40, [S8120-10342]](https://centurymachinery.com/wp-content/uploads/2021/04/10342-1-hufford-A-12-extrusion-_-sheet-stretch-wrap-former-60-T-BJ-28-inch-260-inch-20-inch-sheet-jaws-die-length-72-inch-Serial-40LS-F-300x300.jpg)

![11 tons NAS Plant Division Extrusion Stretch Wrap Forming Press Distance between 3" Gripper Jaws 136" Tension Cylinder stroke 13" Simultaneous Arms Movement, Serial number NAS3-19805, Inventory referenceS8120-10423 - Century Machinery 11 tons, NAS Plant Division Extrusion Stretch Wrap Forming Press, Distance between 3" Gripper Jaws 136", Tension Cylinder Stroke 13", Simultaneous Arms Movement, Serial Number NAS3-19805 [S8120-10423]](https://centurymachinery.com/wp-content/uploads/2021/04/10423-1-NAS-plant-division-stretch-wrap-forming-press-11-tons-3-inch-jawsbetween-jaws-136-inch-tension-str-10-inch-NAS-3-19805Rside-F-300x300.jpg)