Description

SPECIFICATIONS

CAPACITY:

Overall Length of Rolls (actual length 15’ (180”) (4,572mm)

Thickness 0.94" (2.3875mm)

Minimum Radius 1″ (25.4mm)

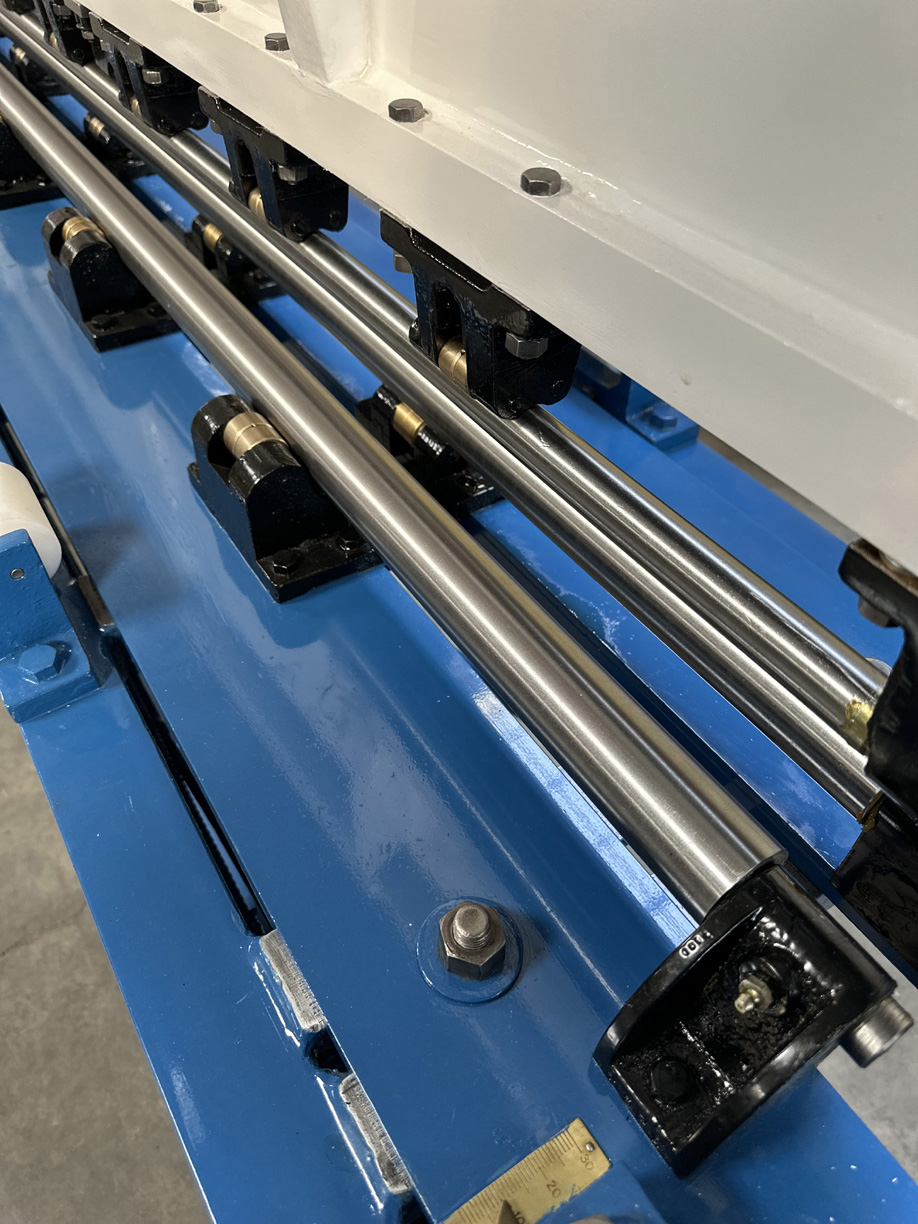

ROLL DIAMETER:

Top Roll 1.625″ (41.275mm)

Bottom Rolls each 1.625″ (41.275mm)

TOP ROLL LIFT MOTORS

Geared motor to screw located on each end.

Mechanical Counter for each end of Top Roll

Each motor with Electric Brake.

BOTTOM ROLLS:

Each with In/Out Adjustment and Indicators located on both end.

TIE ROD BED ADJUSTMENT to put slight bow in bed.

MOTOR DRIVES: Wired 440 volts, 3-phase

All Rolls driven thru Geared Box by 2-Speed Motor 3 hp (2.2kw) & 1 hp. (.74kw) 480 volts

Equipped with Electric Braking.

Top Roll Elevation Motors (Two) each 3/4 hp.(1.52kw) 440 volts

CONTROLS:

Roll Drive Motor Start/Stop Buttons.

Two Roll Speed in Forward/ One Roll Speed in Reverse.

TOP ROLL Up/Down buttons to adjust BOTH END elevation screws at same time.

TOP ROLL Up/Down buttons to independently adjust EACH END elevation screws.

EQUIPPED WITH:

All Outboard Rolls, New Teflon.

Roll Drive Motor with Mechanical Electric Brake.

Top Roll Elevation Motors each with Mechanical Electric Braking.

NOTE: All Rolls removed: Checked for straightness and the re-surfaced.

COMPLETE FACTORY SAFETY GUARDS

Dimensions Approximte 36" FB x 242" LR x 69" Ht. (914.4mm FB x 6146.8mm LR x 1752.6mm H

Approximate Weight 8,400 lbs.

The Following will be done: (a) All roll w2ill be removed & checked for straightness & re-ground.

(b) All contact rolls checked out, and if needed replaced with new rolls.

(c) All Out-board Roll New Teflon.

(d) Elevation Motors with breaking will be tested under power and any deficiencies be repaired.

(e) All Electric tested for workability.

(f) All Rolls Gear Boxes drained of oil, checked-out and new oil replaced. (g) Unit completely re-painted.

Respectfully submitted,

CENTURY MACHINERY CO., INC.

![10 foot Farnham Model 1058-E Aircraft Roll Forming Machine 10 ft. Length - Material thickness 0.094" - Minimum Radius 0.625" - Top Roll 1.0" diameter - Bottom Rolls 1.75" diameter, Serial Number 2-43-14, Inventory Reference R4510-10471 - Century Machinery 10' Farnham Aircraft Roll Forming Machine 10 ft. Length, Model 1058-E, Material thickness 0.0938", Minimum Radius 0.6250", Top Roll 1.0" diameter, Bottom Rolls 1.75 in diameter, Serial Number 2-43-14 [R4510-10471]](https://centurymachinery.com/wp-content/uploads/2021/04/10471-15A-farnham-roll-forming-10-ft-1058-E-thick-0.0938-in-radius-0.6250-in-top-roll-1.0-in-dia-bottom-roll-1.75-in-dia-F-300x300.jpg)